Apr. 12, 2013 Research Highlight Engineering

X-rays in focus

Atomically precise mirrors open up new opportunities for x-ray free-electron laser applications

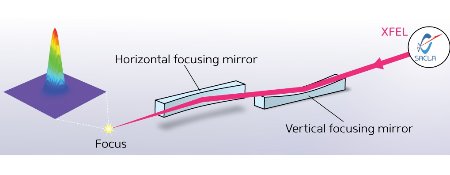

Figure 1: The elliptical mirror system for the SACLA XFEL facility. Two high-precision mirrors focus x-ray radiation from the XFEL into spots of only ~1 micrometer in diameter. Reproduced from Ref. 1 © 2012 H. Yumoto et al.

Figure 1: The elliptical mirror system for the SACLA XFEL facility. Two high-precision mirrors focus x-ray radiation from the XFEL into spots of only ~1 micrometer in diameter. Reproduced from Ref. 1 © 2012 H. Yumoto et al.

X-ray free-electron lasers (XFELs) are powerful analytical light sources that can be used for applications ranging from fundamental materials science to the study of biological processes. A collaborative team including researchers from RIKEN SPring-8 Center (RSC), Osaka University and the Japan Synchrotron Radiation Research Institute have now developed an XFEL mirror system that is able to focus the x-ray beams to a very small spot, providing ultrahigh light intensities that will enable a range of novel experiments1.

X-rays easily pass through most materials, which makes controlling x-ray beams using conventional optics such as glass lenses very difficult, and alternative lens designs have tended to reduce the efficiency of x-ray experiments. “Reduced efficiency and higher absorption of x-rays in the lens damages the optics because absorbed x-rays excite and ionize the atoms in the optical materials,” says Makina Yabashi from the RSC.

A promising method for controlling x-rays is based on reflection, where x-rays are reflected off polished surfaces in a similar manner to the way a satellite dish focuses television signals. The team’s design consists of a pair of elliptical mirrors that reflect x-rays at low angles, providing both horizontal and vertical control of the focused light (Fig. 1).

However, the quality of the reflected beam is strongly dependent on the quality of the reflective surfaces. As x-ray light has a very short wavelength, extraordinarily smooth surfaces are required for the reflection system to be effective. The researchers achieved remarkable atomically smooth surfaces through a combination of techniques including elastic emission machining—a chemical etching technique that provides atomic precision. Fabricated at the Yamauchi Laboratory at Osaka University, the mirrors used in the reflection system had a surface roughness of just 0.13 nanometers on average over the entire mirror length of 40 cm. The mirror itself was fabricated from carbon-coated quartz—carbon has only weak absorption of light at x-ray wavelengths and so does not get damaged by the intense x-ray beams hitting the mirror surface.

The mirrors were tested at the Japanese XFEL facility, known as the SPring-8 Angstrom Compact Free Electron Laser (SACLA). The researchers achieved a focus size of just 1 micrometer, effectively increasing the XFEL intensity by a factor of 40,000. The new mirror system is expected to open up a number of new applications for the XFEL facility. “Applications include the analysis of small particles or nanoparticles, and the study of fundamental physical processes at extremely intense light fields,” says Yabashi.

References

- 1. Yumoto, H., Mimura, H., Koyama, T., Matsuyama, S., Tono, K., Togashi, T., Inubushi, Y., Sato, T., Tanaka, T., Kimura, T., et al. Focusing of X-ray free-electron laser pulses with reflective optics. Nature Photonics 7, 43–47 (2013). doi: 10.1038/NPHOTON.2012.306