Jan. 29, 2016

Seeing through steel and concrete

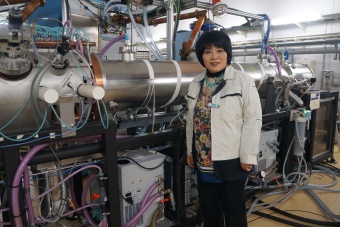

Yoshie Otake, Team Leader

Advanced Photonics Technology Development Group, RIKEN Center for Advanced Photonics

Please briefly describe your current research.

Beams of subatomic particles known as neutrons can be used to nondestructively probe the structure and composition of materials. These uncharged neutrons can penetrate heavy elements, seeing through 3-centimeter-thick steel plates and 50-centimeter-thick concrete slabs. Neutron beams can also be used to detect light elements such as hydrogen, lithium and boron. But researchers have not been able to develop a convenient system that can be used anywhere and anytime.

My team is developing compact, accelerator-driven neutron sources for practical applications. We want to use these systems to assess the inner condition of large infrastructure projects such as highways and bridges that are nearing the end of their life cycles.

How and when did you join RIKEN?

In 1996, I joined a team of researchers at RIKEN collaborating with the Japan Atomic Energy Research Institute (now reorganized into the Japan Atomic Energy Agency) and tasked with constructing the synchrotron radiation facility at Harima, SPring-8 (Super Photon Ring-8 GeV).

How did you become interested in your current field of research?

I have enjoyed physics since high school. I am especially interested in observing coherent behavior in the quantum states of neutrons and searching for the breaking of time-reversal symmetry in the electric dipole moment of the neutron.

Through working on neutron experiments and nuclear reactors that serve as sources of neutrons for research, I became interested in neutron imaging and potential industrial uses of compact neutron sources. I cultivated this interest through a collaboration with the RIKEN VCAD System Research Program, which ran from 2001 to 2011. The project sought to develop a method for modeling and simulating both the shape and volume of an object for use in manufacturing, medicine and the biosciences.

What have been your most memorable experiences at RIKEN?

I get excited when I discover new ways of making neutron beams more compact or neutron detection easier. I also really enjoy discussing with industry representatives about ways of using our systems to nondestructively inspect their products.

RANS and Otake © 2016 RIKEN

RANS and Otake © 2016 RIKEN

What is the best thing about working at RIKEN?

The best thing about being a researcher at RIKEN is its free and engaging atmosphere. We can discuss many areas of interest with high-level researchers and have the flexibility to start new research projects.

What has been the most interesting recent discovery in your field?

In 2015, Takaaki Kajita and Arthur McDonald were awarded the Nobel Prize in Physics for discovering that an elusive and abundant elementary particle called the neutrino oscillates between different identities, and hence has mass. This finding contradicts the standard model of particle physics, which requires neutrinos to be massless.