Oct. 1, 2013

Development of next-generation differential mobility analyzer (DMA)

RIKEN No.: 07734

Inventors

Takaaki Orii and Satoshi Kudo

Summary

Expectations are high for nanoparticles in applications such as materials that deliver new properties that depend on size. Differential mobility analyzers (DMAs) have been utilized widely in fields such as material development and environmental measurement as a device to sort nanoparticles floating in gas phase by their size. As nanotechnology has advanced in recent years, there is a tendency in classifying particles to include a larger variety of substances such as organic-inorganic hybrid particles and bioparticles. When substances with high particle vapor pressures, such as organic components, evaporate in the process of classification in DMA, the particle size itself changes and it may be impossible to conduct size sorting precisely. In addition, it is difficult to predict the volatility in advance as it also depends on the particle composition and size, making it necessary to analyze the measurement results carefully.

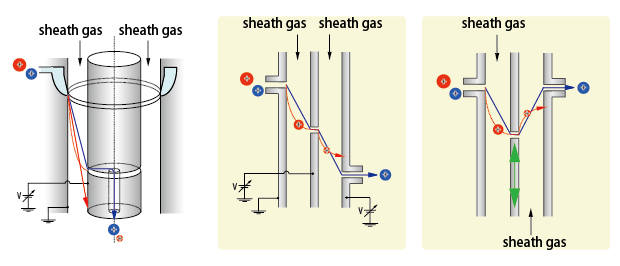

To solve the above problem and enable more precise size sorting of nanoparticles, our laboratory has designed a next-generation DMA with a structure connecting two layers of parallel-plate-type classification layers in tandem (see figure below), as opposed to the conventional DMAs with one double-cylinder-type classification layer. The characteristic of this next-generation DMA is the simple structure comprising two classification layers with 3 electrodes. By applying this structure, particles that change in size during the classification process in the first layer can be eliminated on the second layer, and thus it is now possible to prevent generation of wrong particle size distribution caused by volatility of the particles. Furthermore, adoption of multiple classification layers promises to improve separation of particles from gas.

It is now also possible to simply optimize the distance between slits that is necessary for classification by only moving the position of the middle electrode, as the sheath gas flow direction is reversed in one classification layer. It also offers the advantage that the positions of other devices and piping around the DMA do not have to be changed.

Another structural characteristic is that the sample gas duct can be made shorter in this parallel-plate-type DMA. By improving the penetration of nanoparticles with sizes equivalent to ions and clusters, the next-generation DMA is expected to enable efficient sorting and high-sensitivity analysis.

A conventional DMA(left) and a next-generation DMA(right)

References

- 1. Japanese patent No.5652851, US patent 8698076, CN patent ZL201110033972.7