Jun. 10, 2016

Innovations Contributing to the Application of High-Temperature Superconducting Materials

RIKEN No.: 07969, 08235, 08045

Inventors

Masato Takahashi, Xinzhe Jin, Yoshinori Yanagisawa, Hideaki Maeda (NMR Facility)

Background

Second-generation high-temperature superconducting wire using a rare earth material (REBCO wire) has excellent high-current density characteristics in high magnetic field. Compared with conventional superconducting wire, and is expected to be an innovative technology that lead to advances in various fields such as a significant compactification of high magnetic field NMR magnets, etc., and to significant reductions in CO2 emissions. The practical application of REBCO wires requires a technology system that is different from conventional superconducting technology. We have clarified the problems to be overcome and successfully developed technology for solving these problems ahead of the world.

Summary

The following technologies required for the practical application of REBCO wires will be described:

- 1."a polyimide-coated high-temperature superconducting wire" being a coil technology without property degradation;

- 2."a superconducting joint technology between high-temperature superconducting wires" being a technology for realizing wire lengthening and a Persistent current mode; and

- 3."an NMR signal transmitting and receiving antenna fabrication technology in an ultra-high magnetic field region" being a high-frequency antenna technology capable of coping with high magnetic fields of 1.02 GHz (24.0 T) NMR.

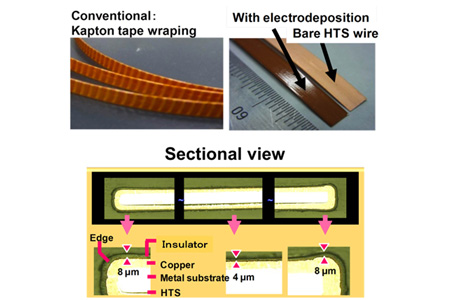

Fig. 1: Polyimide Electrodeposition Coated REBCO Wire

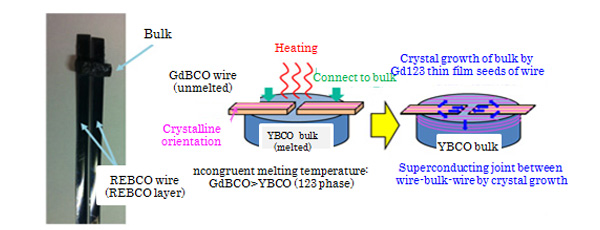

Fig. 2: "a superconducting joint technology between high-temperature superconducting wires" being a technology for realizing wire lengthening and a Persistent current mode; and

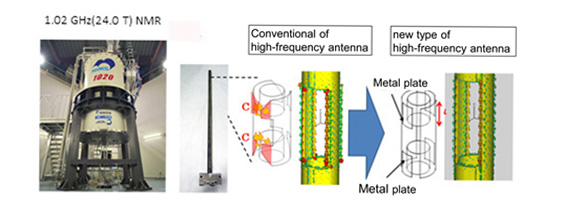

Fig. 3: "an NMR signal transmitting and receiving antenna fabrication technology in an ultra-high magnetic field region" being a high-frequency antenna technology capable of coping with high magnetic fields.

Merits

Polyimide Coated High-Temperature Superconducting Wire

- The thickness of the insulating layer can be as thin as one-tenth or less of the conventional thickness.

- Coating formation of uniform thickness is possible throughout the wire material including the corner portion.

- This could be applied to all coil manufacturing methods including epoxy resin impregnation, and would dramatically improve the current density of the superconducting coil.

Superconducting Joint Technology between High-Temperature Superconducting Wires

- Due to the realization of the Persistent current mode, the power supply is not required to be constantly connected, therefore allowing further reduction in cost and higher stabilization of the magnet.

NMR Signal Transmitting and Receiving Antenna Fabrication Technology in an Ultra-High Magnetic Field Region

- Since the antenna for solution NMR can cope with an ultra-high frequency and ultra-high magnetic field, NMR measurements with high sensitivity and high resolution can be achieved.

Applications

- Development of NMR and MRI in an Ultra-High Magnetic Field that has not been realized until now

- Weight Reduction in a Superconducting Magnet in a Superconducting Linear Motor

- Practical Application of a High-Temperature Superconducting Device in Basic Science, Medical Care, and Engineering Field

References

- 1. Japanese patent application No.2012-100477, EP12189570.0, US13/658330

- 2. Japanese patent application No.2012-148036, EP13174124.1

- 3. PCT/JP2014/077966

- 4. T. Takematsu et al., Physica C, 470, (2010) pp. 674-677

- 5. Y. Yanagisawa et al. Physica C, 476, (2012) pp. 19-22

- 6. Y. Yanagisawa et al. Physica C, 495, (2013) pp. 15-18