Feb. 28, 2022 Research Highlight Chemistry

Strong, stretchy, self-healing polymers rapidly recover from damage

A catalytic combination of multiple monomers generates a polymer that has an exceptional ability to self-heal

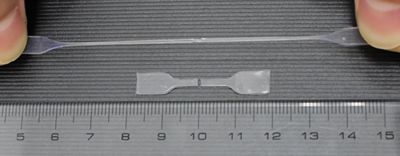

Figure 1: After being cut with a razor blade (bottom), the polymer largely self-healed within a minute upon the pieces being gently put together (top). After 5 minutes, it recovered 99% of its toughness and 97% of its tensile strength. © 2022 RIKEN Center for Sustainable Resource Science

Figure 1: After being cut with a razor blade (bottom), the polymer largely self-healed within a minute upon the pieces being gently put together (top). After 5 minutes, it recovered 99% of its toughness and 97% of its tensile strength. © 2022 RIKEN Center for Sustainable Resource Science

A polymer that heals itself with unprecedented speed and efficacy when cut—almost completely recovering its original strength within minutes—has been developed by RIKEN researchers1. It was produced using an advanced catalytic method for combining multiple precursors into a single polymer in a controlled fashion.

Increasing the structural complexity of polymers offers great promise for developing new materials with novel or improved properties. The controlled synthesis of complex polymers remains challenging, however.

Zhaomin Hou of the RIKEN Center for Sustainable Resource Science and his colleagues recently developed a controlled catalytic method for combining non-polar and polar olefin monomers into a single polymer. “We previously discovered that we could synthesize multiblock copolymers that exhibited excellent elasticity and self-healing by using the two-component copolymerization of non-polar ethylene and polar methoxyaryl-substituted propylenes by a half-sandwich scandium catalyst,” says Hou.

The two-component polymers’ properties depended strongly on the methoxyarylpropylene used. “This raised the intriguing question of whether a three-component ‘terpolymer’ of ethylene and two different methoxyaryl-functionalized propylenes would show unique synergistic effects on the mechanical and self-healing properties,” adds Hou.

Now, Hou, four RIKEN colleagues and a collaborator have confirmed that terpolymers can show unprecedented mechanical and self-healing performance. Their elastomeric polymer could be stretched to almost 14 times its original length before breaking. And when cut in two, the polymer healed itself within 5 minutes to recover 99% of its toughness and 97% of its tensile strength (Fig. 1).

The material’s exceptional performance can be explained by its unique molecular structure, Hou notes. The polymer consisted of three nanoscale component subsections, or ‘blocks’, with quite different physical properties, the team showed. Each methoxyarylpropylene formed relatively long alternating ethylene-methoxyarylpropylene sequences. One methoxyarylpropylene formed sequences that were soft and flexible, whereas the other gave sequences that were hard. A third sequence type, consisting of relatively short ethylene−ethylene blocks, was crystalline in nature.

“The polymer’s excellent elastomeric and self-healing properties are due to the formation of this nanoscale three-dimensional network,” says Hou. The long, soft sections form a highly flexible matrix, within which are hard and crystalline sections that rapidly re-aggregate after the material is cut, thereby self-healing any damage.

This polymerization method using a scandium catalyst offers many avenues for further polymer development. “We anticipate our approach will enable additional functions to be easily incorporated into this novel class of self-healing polymer,” says Hou. “And we expect our self-healing mechanism will guide the design and creation of various new self-healing polymers through microstructural control.”

Related contents

- Now polymers can self-heal, even when wet

- Scientists discover new type of self-healing material

- A mechanically robust but readily repairable polymer

Reference

- 1. Yang, Y., Wang, H., Huang, L., Nishiura, M., Higaki, Y. & Hou, Z. Terpolymerization of ethylene and two different methoxyaryl-substituted propylenes by scandium catalyst makes tough and fast self-healing elastomers. Angewandte Chemie International Edition 60, 26192–26198 (2021). doi: 10.1002/anie.202111161